The Science Behind Carbon Fiber: How Mastermate is Redefining Material Excellence

The Molecular Magic of Carbon Fiber

At its core, carbon fiber is a polymer composed of long, tightly interlocked carbon atoms arranged in a crystalline structure. This unique atomic arrangement gives carbon fiber materials their extraordinary properties:

✔ High Tensile Strength – Stronger than steel at a fraction of the weight

✔ Low Thermal Expansion – Maintains stability in extreme temperatures

✔ Chemical Resistance – Impervious to corrosion, acids, and solvents

✔ Electrical Conductivity – Ideal for EMI shielding applications

Mastermate leverages these properties to engineer carbon fiber composites that outperform conventional metals and plastics.

How Carbon Fiber is Made: Mastermate’s Precision Process

-

Precursor Selection

-

We use high-quality polyacrylonitrile (PAN) or pitch-based fibers for optimal strength.

-

-

Oxidation & Carbonization

-

Fibers are heated in controlled environments to remove non-carbon elements, leaving pure carbon fiber.

-

-

Weaving & Layup

-

Fibers are woven into sheets or molded into 3D structures for different applications.

-

-

Resin Infusion

-

Epoxy, vinyl ester, or thermoplastic resins are applied to enhance durability and stiffness.

-

-

Curing & Finishing

-

The material is cured under high pressure and temperature, then CNC-machined for precision parts.

-

Industry-Leading Applications of Mastermate’s Carbon Fiber

1. Aerospace & Defense

-

Aircraft wings & fuselage panels – Reduce weight while maintaining structural integrity

-

Satellite components – Withstand extreme thermal cycling in space

-

Drone frames – Enhance flight efficiency with ultra-lightweight builds

2. High-Performance Automotive

-

Carbon fiber car body panels – Improve fuel efficiency without sacrificing safety

-

EV battery enclosures – Lightweight yet fire-resistant protection

-

Racing components – Maximize speed and handling in competitive motorsports

3. Sports & Consumer Goods

-

Golf clubs & tennis rackets – Optimize swing speed and control

-

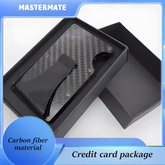

Luxury watches & phone cases – Combine elegance with impact resistance

-

Bicycle frames – Deliver stiffness for efficient power transfer

4. Industrial & Robotics

-

Robotic arms – Reduce inertia for faster, more precise movements

-

Medical imaging components – Provide strength without interfering with scans

-

Wind turbine blades – Increase energy output with lighter, more durable designs

Why Mastermate’s Carbon Fiber Stands Out

✅ Custom Formulations – Tailored resin systems for specific strength, flexibility, or thermal needs

✅ Precision Machining – CNC, laser cutting, and waterjet capabilities for flawless finishes

✅ Rigorous Testing – Every batch undergoes stress, fatigue, and environmental testing

✅ Sustainable Solutions – Recyclable materials and energy-efficient production

The Future of Carbon Fiber: What’s Next?

🔹 AI-Optimized Designs – Machine learning for stronger, lighter composite structures

🔹 Mass Production Breakthroughs – Lowering costs for broader automotive and consumer adoption

🔹 Smart Carbon Fiber – Embedded sensors for real-time structural health monitoring

Experience the Mastermate Difference

At Mastermate, we don’t just supply carbon fiber products—we engineer solutions that push boundaries. Whether you need a prototype or full-scale production, our expertise ensures optimal performance for your application.

Contact us today to discuss your carbon fiber needs!